PILOT 2 (pt. 2): Future Fabrics Expo

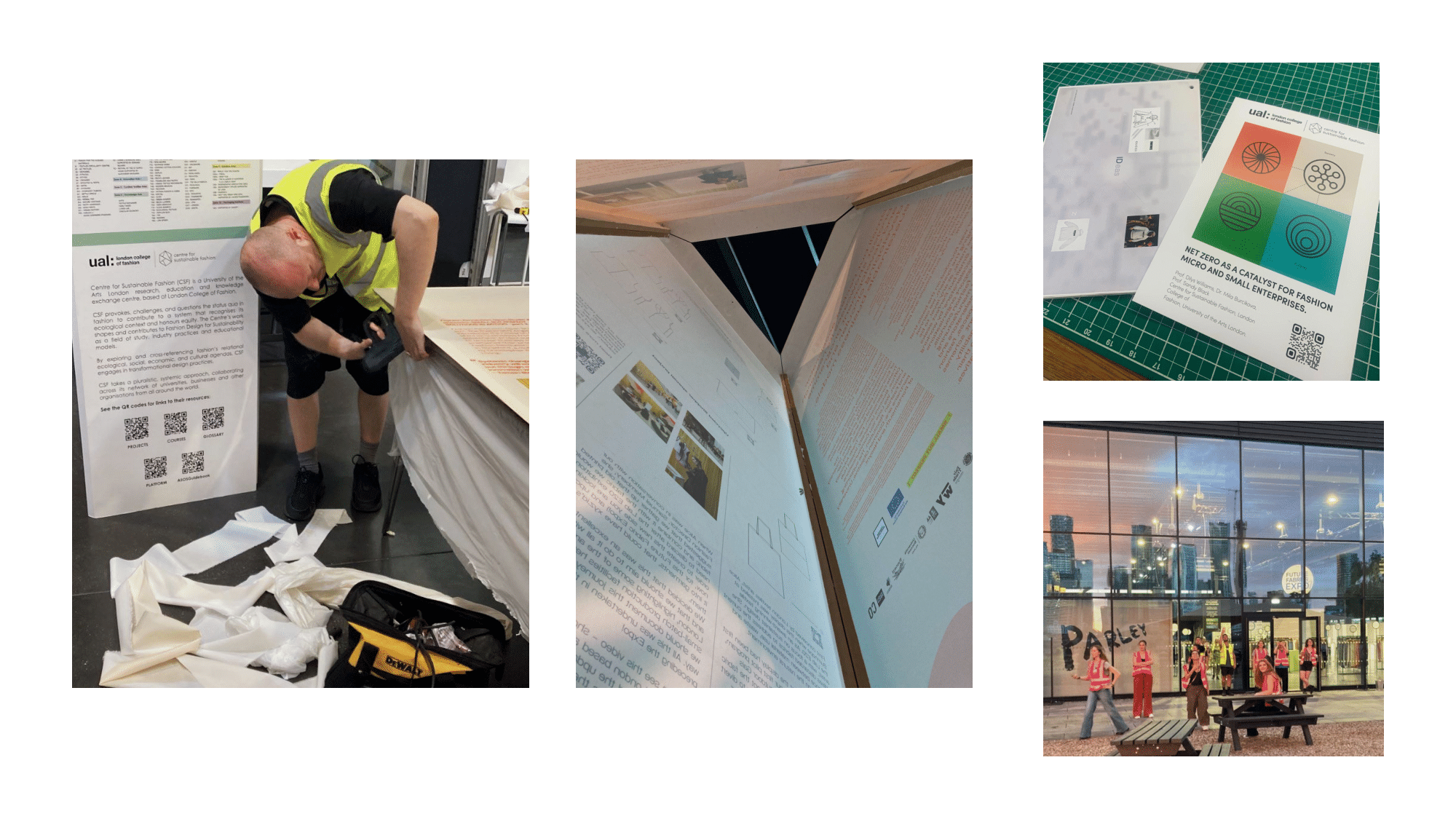

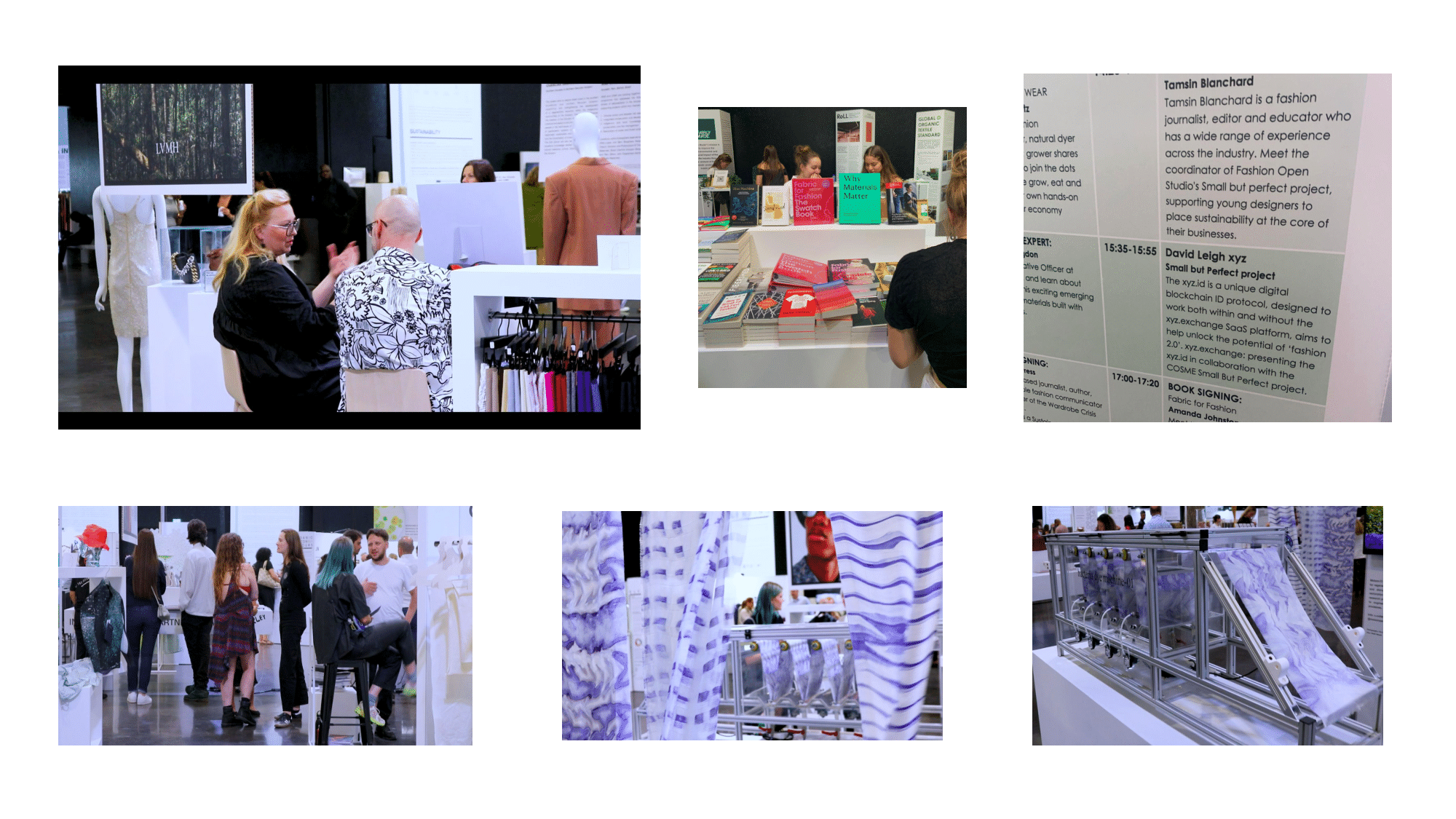

For this part of our second pilot we continued our journey with the Small But Perfect cohort (see part 1 here), this time showing our three sided display at The Sustainable Angle’s inaugural Knowledge Hub area within their 2023 annual Future Fabrics Expo.

It was during our residency at the Lab E20 in Stratford, that we realised - once again - we were going to have to update the content on the display for the next activation, and therefore again have waste fabric to deal with.

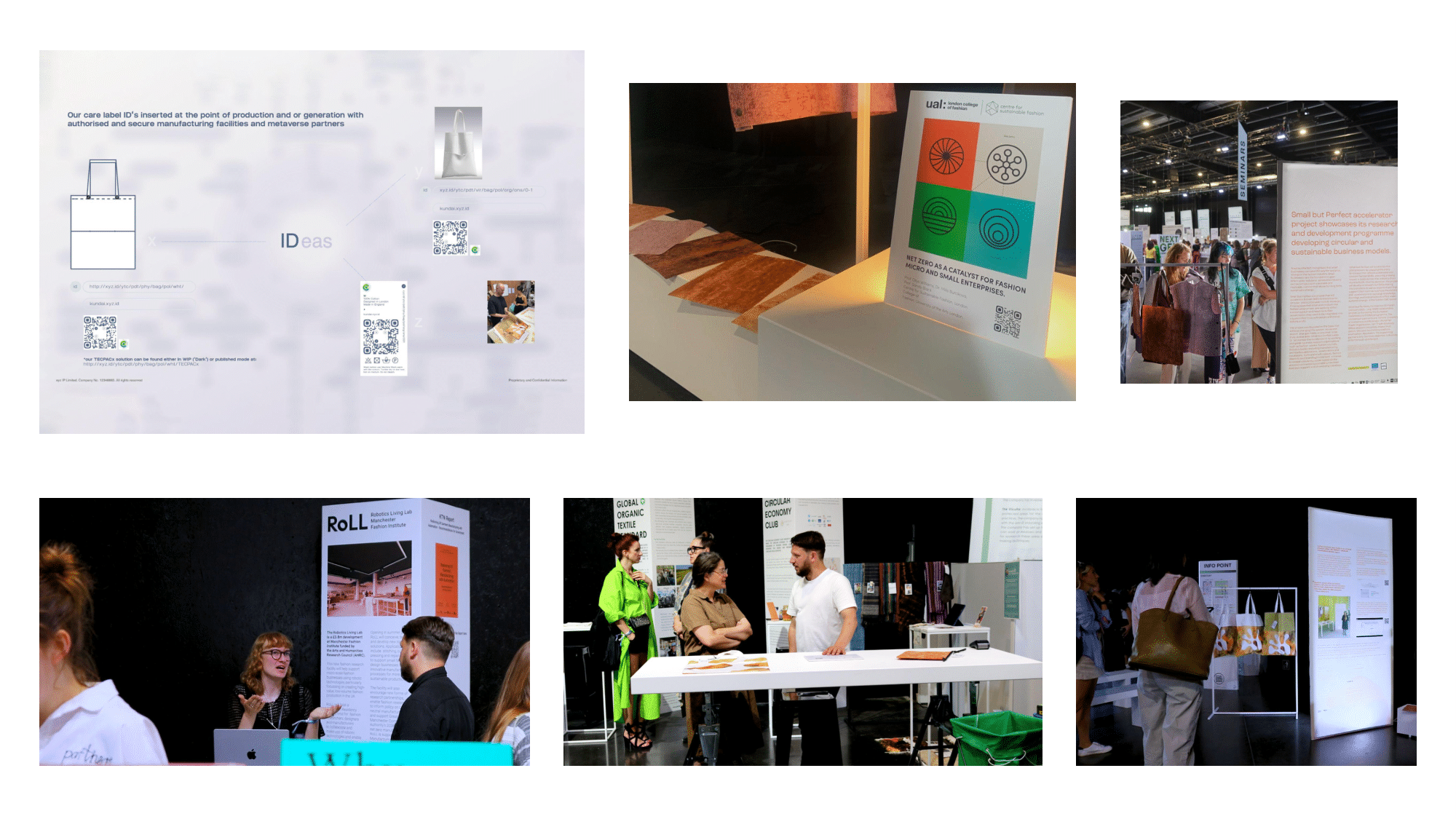

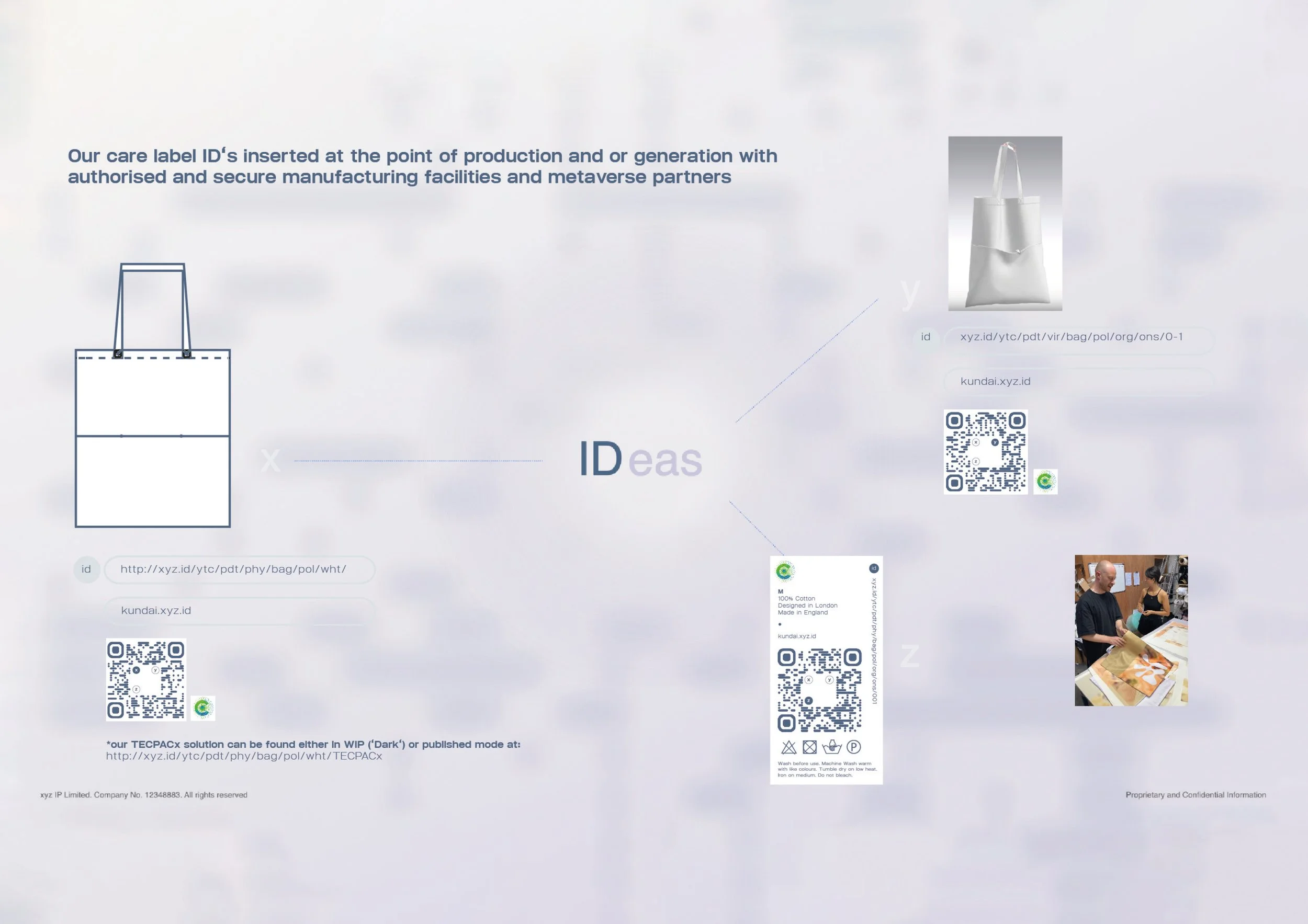

This is when award wining London textile artist, Alice Burnhope, with her focus on sustainist design, first suggested a solution to our dilemma. Alice utilises discarded fabrics to address the current imbalance between material use, waste and the effect on the natural environment. Alice was aware that the display had been first used in 2021 as part of our first pilot program, Class of 2020Vision, at the outdoor Gaia’s Garden event, and that we had kept the fabric from this in the hope of finding a way to divert it from landfill. The fabric, sourced from our Tottenham based partner, Lemonhead Prints Ltd, needed to have certain qualities, such as: be waterproof, stretch over a frame in a certain way (without distorting the printed image) and had to amplify the LED light placed within it. All this meant that regular recycling options were limited. It was in conversation with our fashion director, Samuel Membery and good friend and multidisciplinary artist, Kundai (who had provided the music to the opening night at the Lab E20) that the idea to upcycle the fabric into bags was decided. Alice recommended that we combine the fabric from previous events with fabric we would be left with after the Lab E20 exhibition and upcycle it into products, that could themselves have xyz.ids’ on and developed via our new Smart Tech Pack™ feature . We saw this as a perfect opportunity to further research, test and develop our latest thinking around the solution!

We decided that this was an excellent activation and that we should aim to do it all within London, highlighting some of the amazing small-batch production facilities in the city, and that we should document this journey along the way. All this was undertaken in the week preceding the Expo.

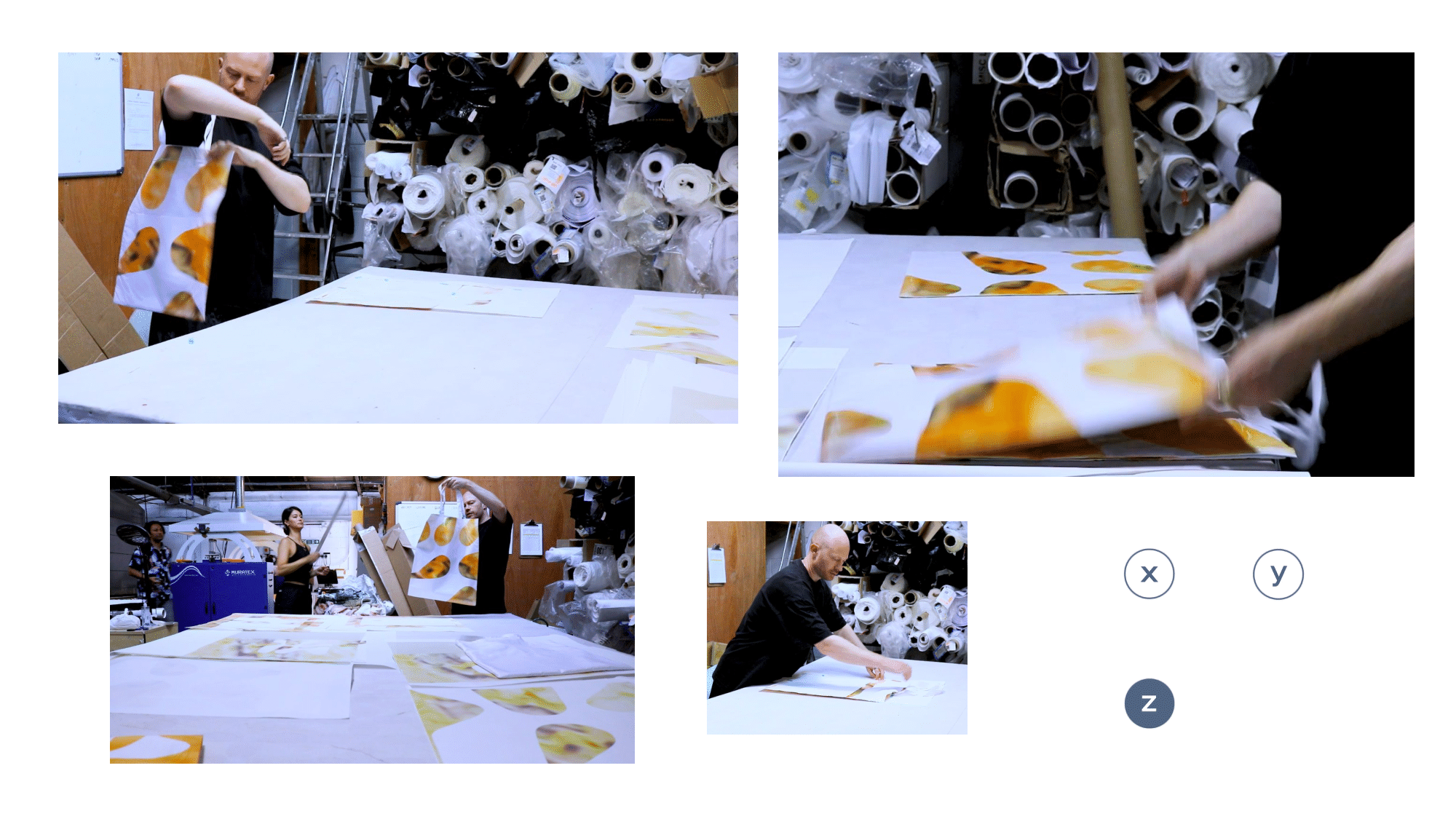

We started day 1 of our New Design Journey in Stratford, once we had reviewed and recovered the fabric at the Lab E20, by taking it on to accessories brand Been London, who specialise in transforming waste materials into products. During this visit we decided that the simplest and most effective thing was to create a flat conceptual designer Tote bag, by layering the relatively thin fabric in order to give the required weight and form, with the lining retaining the original print and the exterior surface having an overprint design by Kundai.

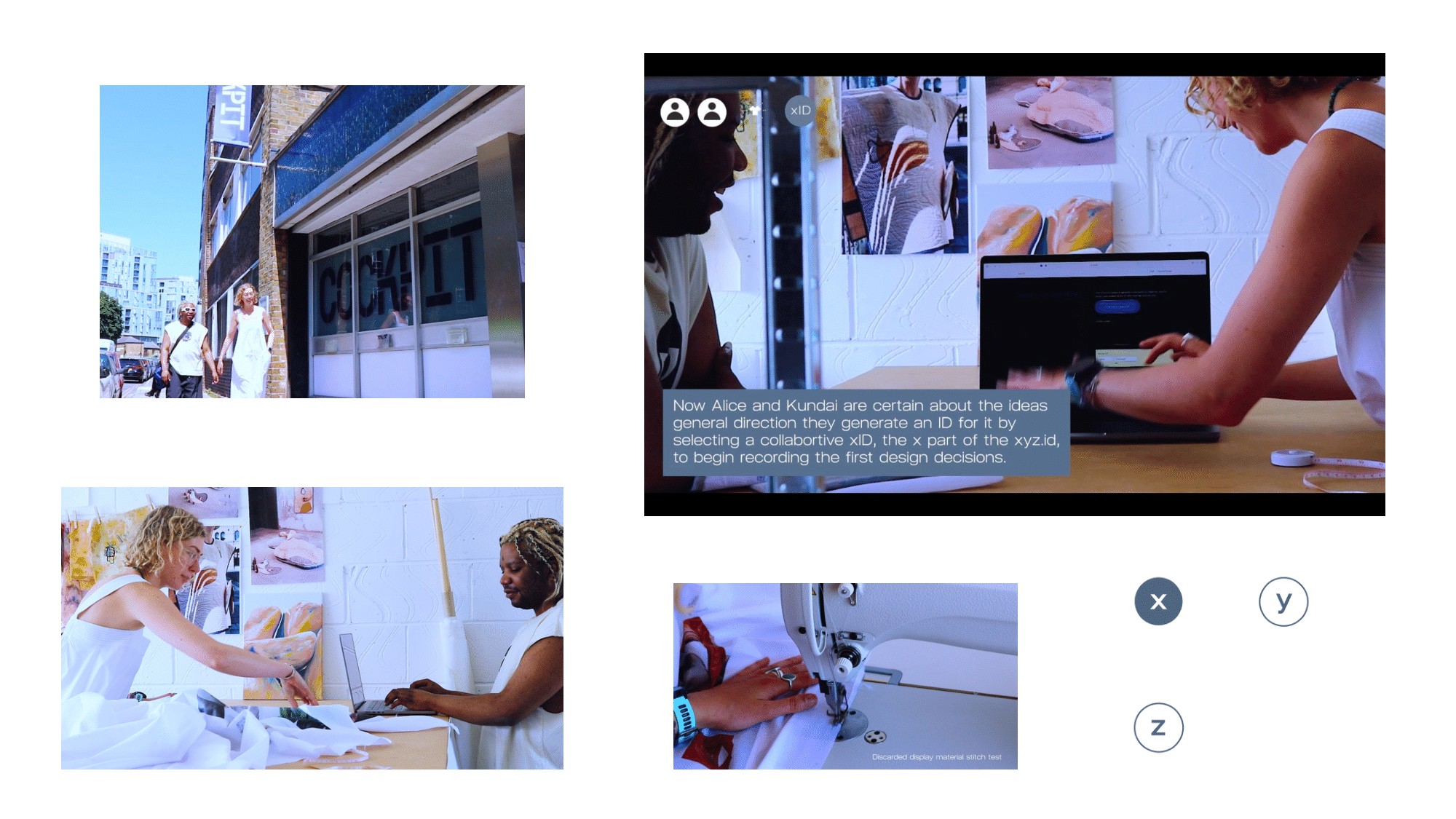

Later that day we took the fabric over to Alice’s studio at Cockpit in Deptford. Here we made a few final tests on the fabric and decisions around the surface designs general direction, before committing to officially opening and generating a new unique design ID (xID): xyz.id/ytc/pdt/xyz/bag/pol/xyz (at this point it is given a unique serial number, as well as being defined as a bag made from a material that is predominantly polyester).

Once this was done Kundai opened our prototype Smart Tech-Pack™ (TECPACx), contained within the xID, and uploaded his initial print design to the Surface Design section, thereby updating the SKURL™ to reflect the designs predominant colour, orange: xyz.id/ytc/pdt/xyz/bag/pol/org

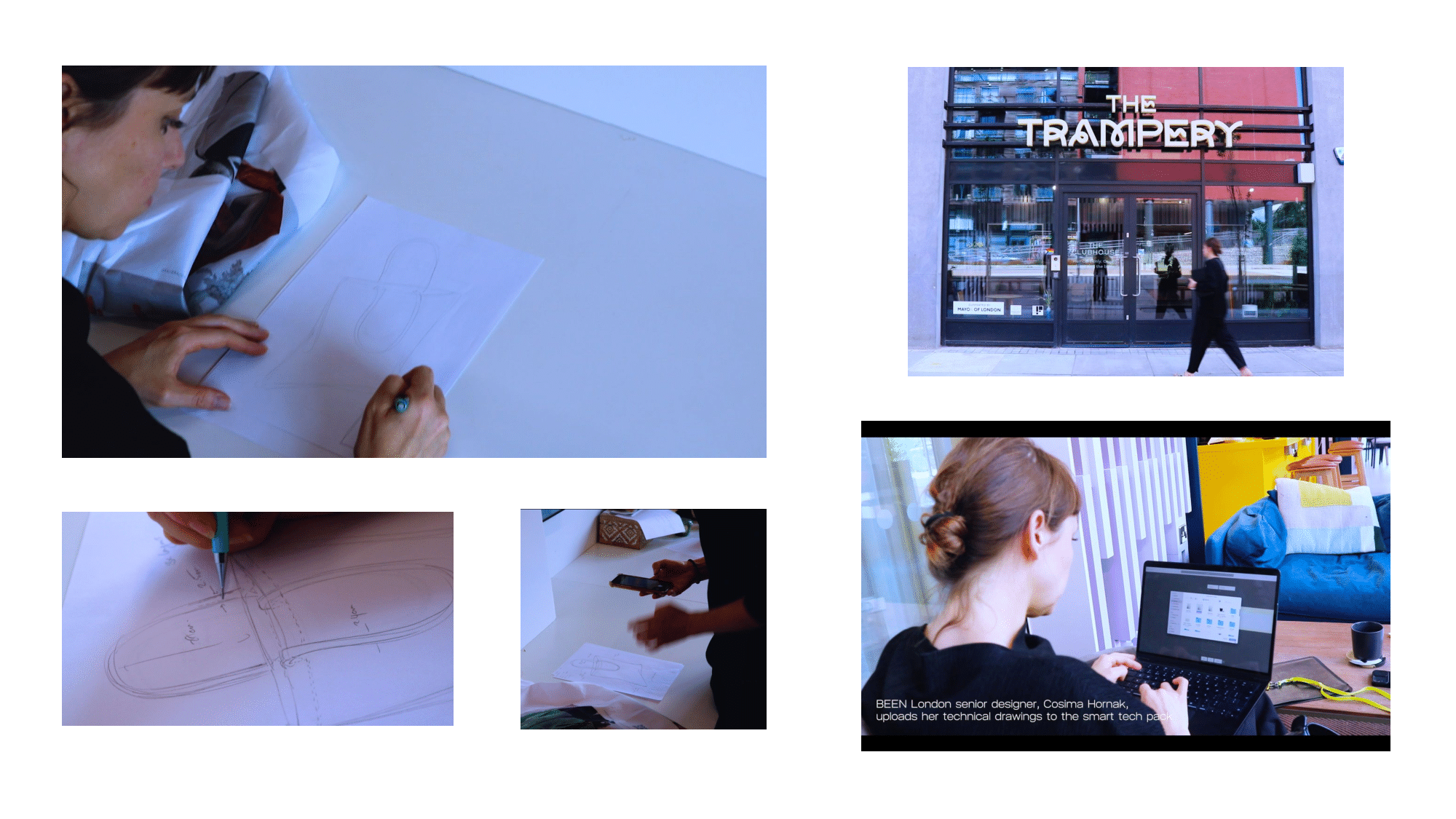

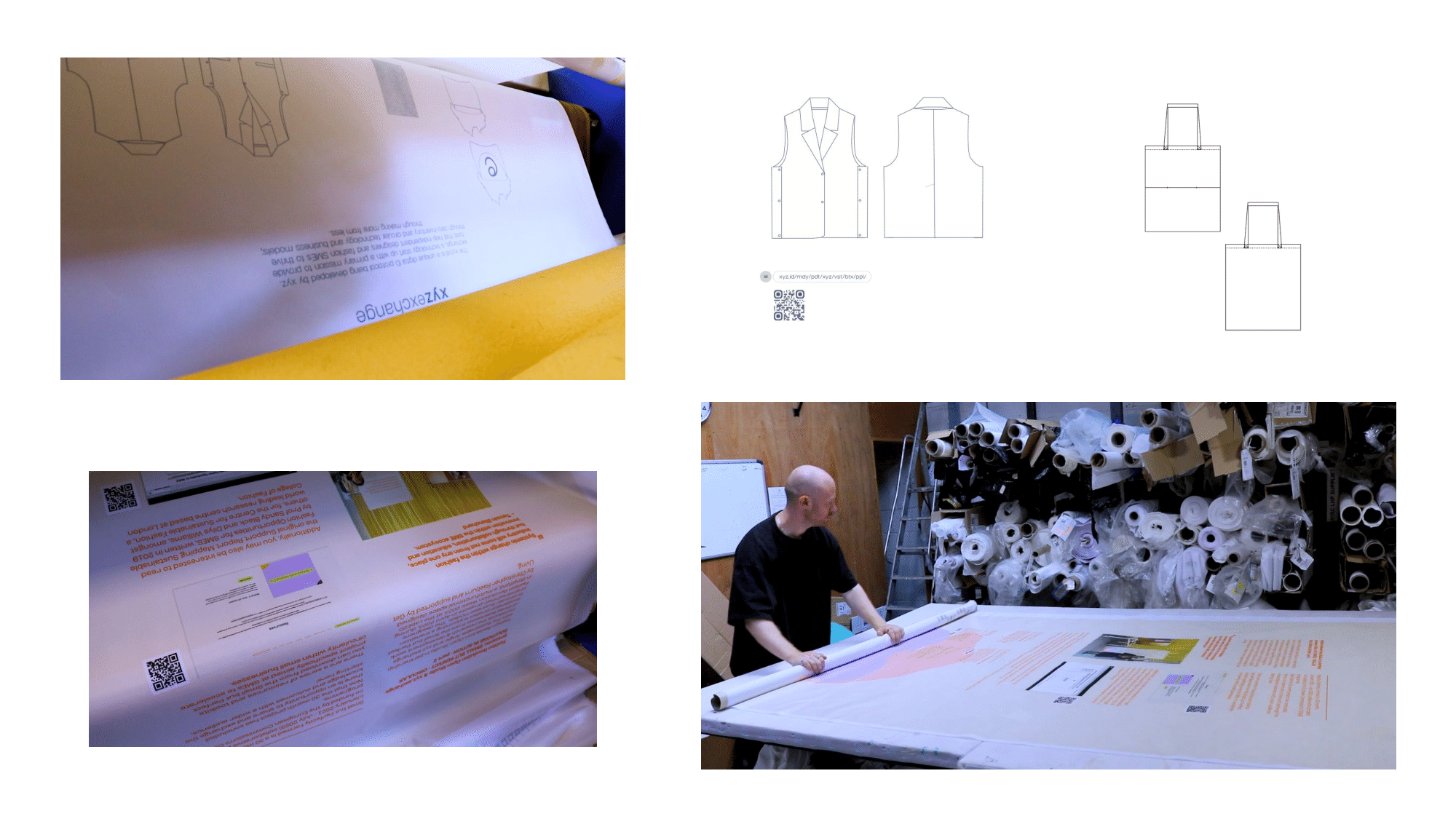

The following day (Day 2) we returned to The Trampery, Fish Island Village, to work with Been London’s Head of Design, Cosima Hornak, on the final design specs. Once this was done, she captured and uploaded this to the TECPACx, which was then in turn shared with, opened and downloaded by Nailya Belkacemi, from her Pattern Studio location around the corner. It was great to see Nailya - one of our first pilots supporters in 2020 - joining us for this next part of our journey!

Cosima also walked around there to sit with her and discuss the design in person - they happen to be neighbours, a shining example of how the Trampery Fish Island are bringing multiple nodes of the supply chain into one local eco-system!

When there she watched as Nailya created a virtual prototype in CLO and therefore generating the first yID for this design, which was then placed within the TECPACx as its primary purpose was to aid in the eventual production process: xyz.id/ytc/pdt/vir/bag/pol/wht/ons/0-1

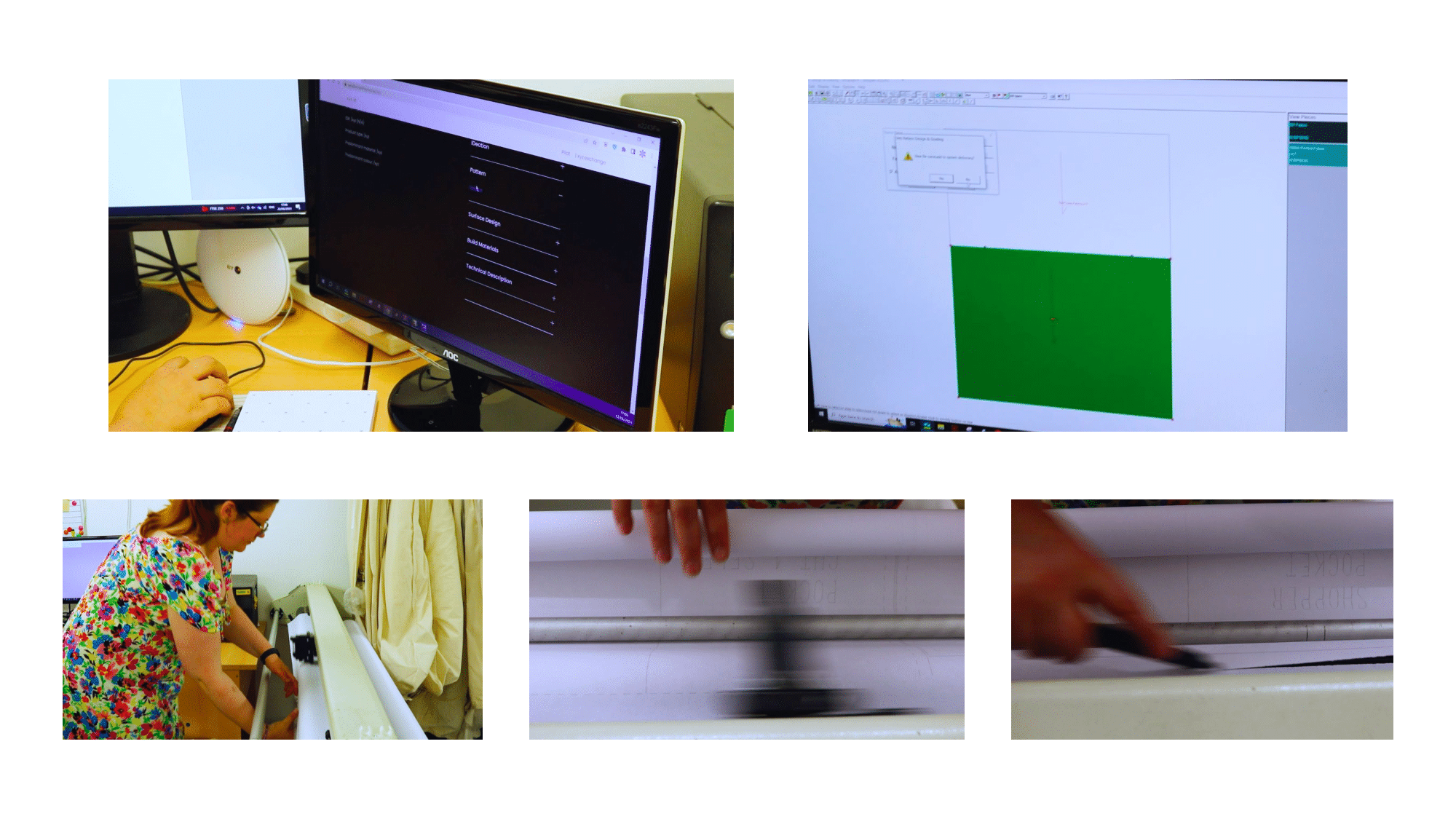

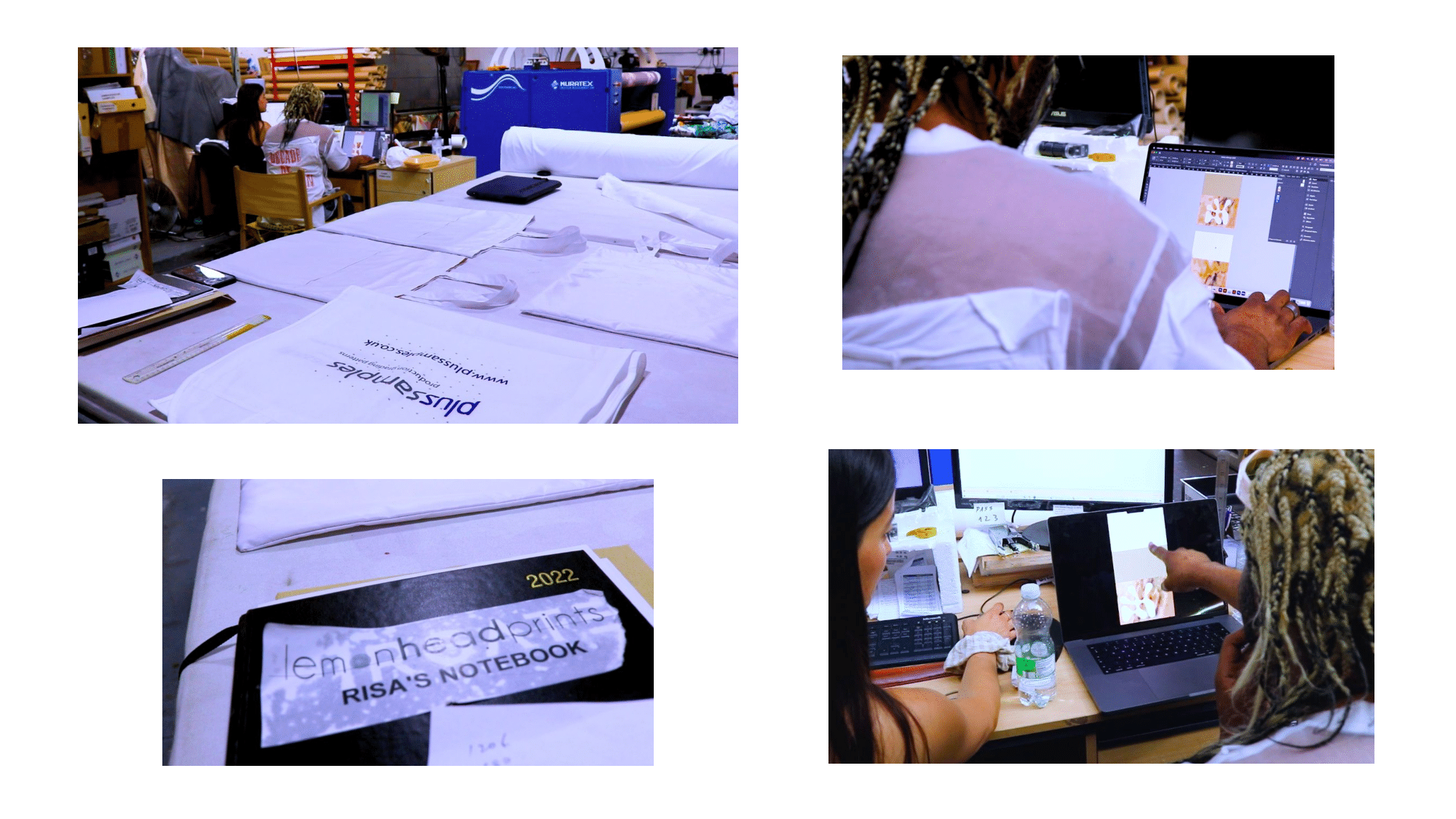

Day 3 of our New Design Journey started out in Wilsdon at Nailya’s Plus Samples factory. Here she opened the TECPACx to review the design so that she could create a digital pattern which would be used by her pattern cutters to cut the material. Once she had done this she uploaded that cutting file to the xID, via the TECPACx Pattern section.

We first created a physical prototype to make sure the design worked in the real world. Unlike with the virtual prototype we didn’t generate a prototype zID yet, as this was only the first stage of its sampling.

Once the physical prototype had been approved and signed off we were then ready to move on to the manufacturing stage, whereby 3 official replicas of the design IP are issued as they come off the run.

On day 4 we took the partially finished prototype and direct-to-consumer products of the design to our longstanding partners, Lemonhead Prints, to bring the story full circle, back to where it all started in 2021 (which is how we first met them!).

Once Founder, Abishek Sharma and his production manager, Risa Moro, had assisted Kundai to prepare his art work for print they turned on the large format dye sublimation printer and ran the prototype bag through the machine. As this came off the final part of its production run it was time to generate its corresponding prototype zID, which like the virtual prototype, is naturally placed within the TECPACx. However, unlike the virtual version, a care-label (bearing its prototype zID) was fixed to the physical prototype: xyz.id/ytc/pdt/phy/bag/pol/org/ons/0-1

This now meant we were able to complete the actual market-ready products, therefore generating their three zIDs and in turn their unique corresponding care-labels, which are fixed to these direct-to-consumer physical products:

Lastly, in preparation for the xyz.exchange Future Fabrics Expo installation, the fabric for our new display was run through the same process and fabric.

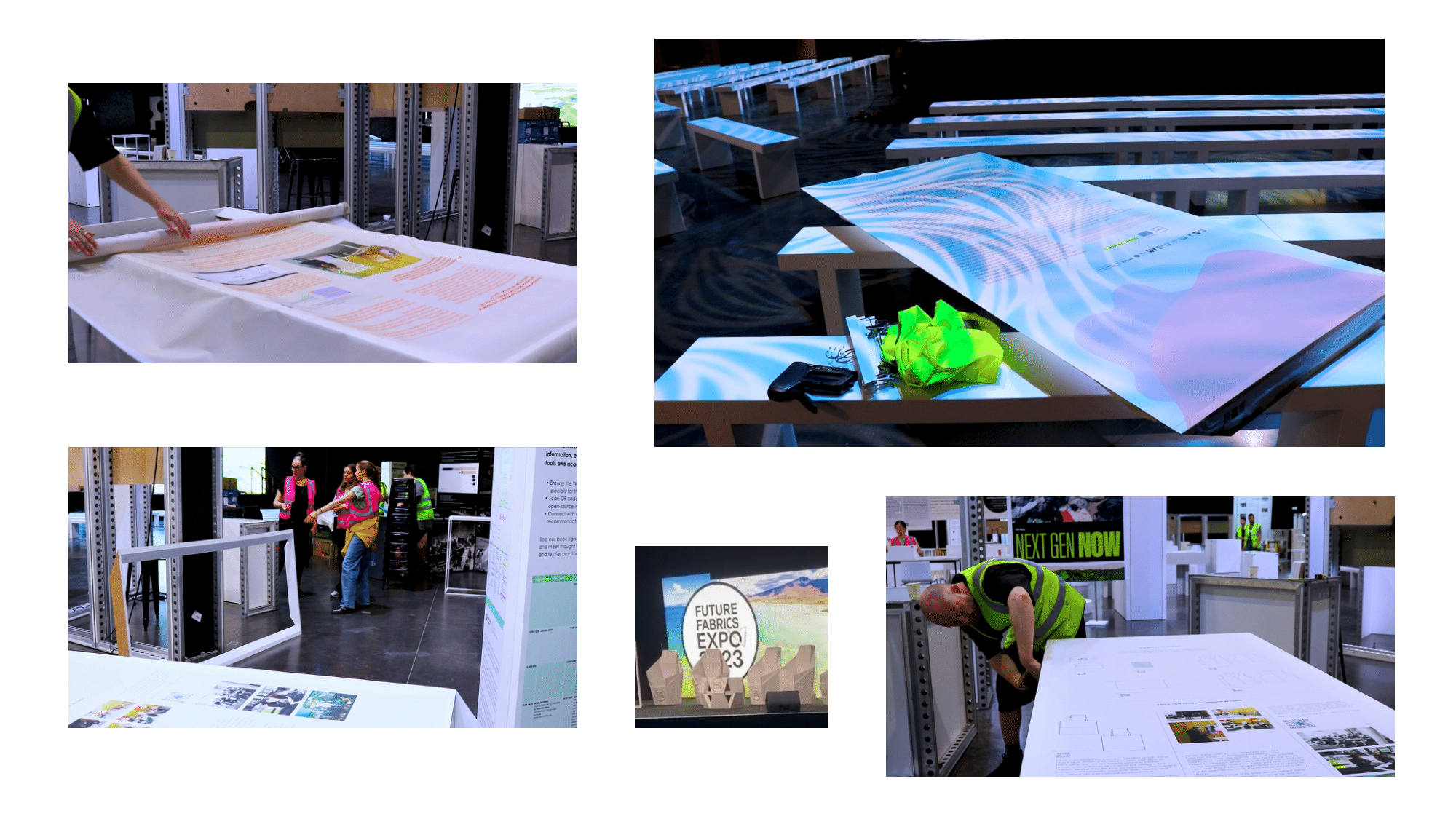

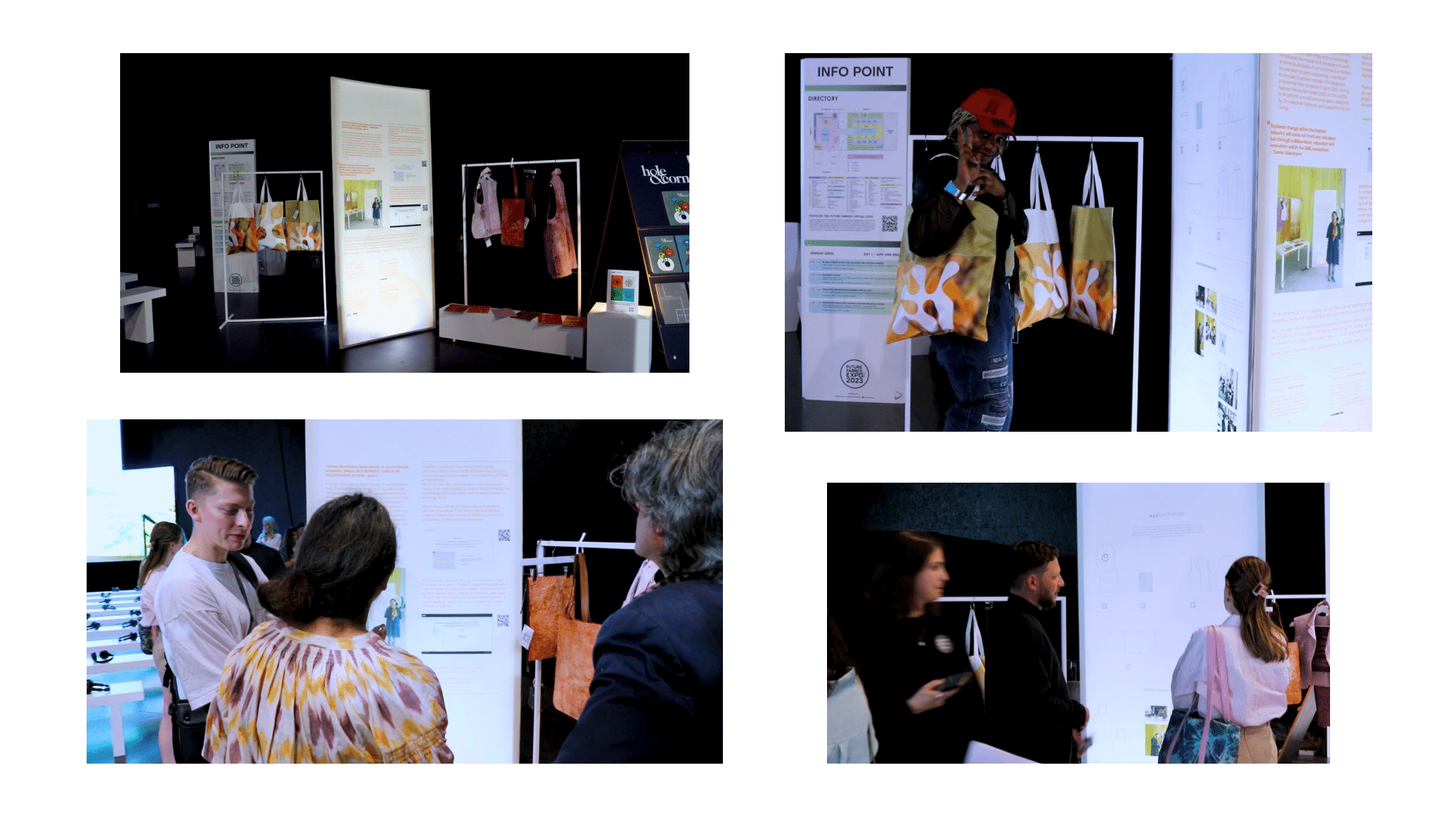

The next day (Day 5) we took our finished bags, complete with their xyz.ids, along with our updated display content on to the Future Fabrics Expo in order to have everything set up and ready for the opening the next day (Day 6), which completed our New Design Journey.

We were excited to spend 3 days at the Expo sharing this story and the latest version of our solution to the industry community and to connect with friends - both old and new. We were also very pleased to have this opportunity to present a conclusion to the Small But Perfect project, both our (small!) part in that, specifically the How To Showcase Small But Perfectly Guide, as well as the wider finalised Resources page.

Amongst other things, this was the first time we demonstrated the Digital Product Passport (DPP) aspect of our solution, here shown using the one native to our system.

We were also proud to be surrounded in the Knowledge Hub by research content which also focused on the interesting intersection between MSME fashion brands and sustainability; considering how Independents can thrive - outside of the traditional system - through making more [value] from less [units]. Where lowering the barrier to entry (and sustaining oneself once there) is equally about reducing waste, through utalising new rapidly emerging Zero-inventory and Circular technology and Business Models.

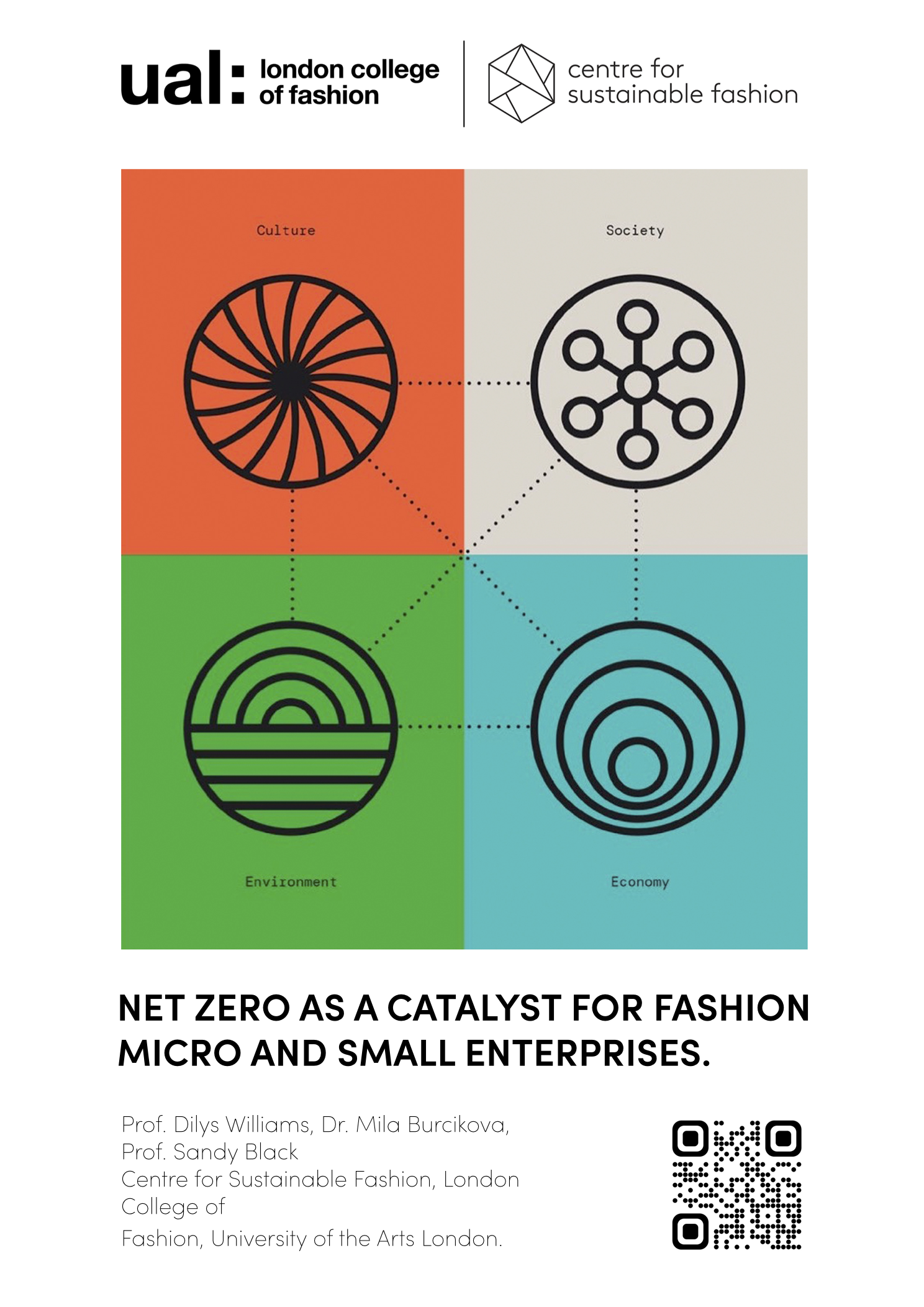

Most notably here, we incorporated the Centre for Sustainable Fashion’s recent Net Zero As A Catalyst For Fashion MSMEs report into our display area. Which was a continuation an earlier Support Report Mapping Sustainable Fashion Opportunities for SMES, also referenced on our display, especially with regard to how this report informed the EU COSME funded Small But Perfect project.

Another organisation placed within close proximity of us and considering similar problems and opportunities within fashion systems, was MMUs Robotics Living Lab (RoLL), a new fashion research facility to help support micro-scale fashion businesses using state of the art technologies for more sustainable and local production.

We received valuable feedback during along the way, which we will now use to inform the next part of our second R&D pilot in Q1/2 2024, which will aim to research and develop our TECPACx solution in more detail.